Embark on a transformative journey toward sustainability with NVTPE's game-changing innovation – the 100% Recycled TPE Pellets. Painstakingly crafted from end-of-life tires and post-consumer plastic waste, our pellets signify a bold stride towards a greener future. Distinguished by their remarkable versatility, these sustainable pellets cater to diverse industry needs without compromising on quality.

Discover the endless possibilities, from enhancing product performance to minimizing production costs. Click to delve into the future of materials that not only meet but exceed industry standards. Join us in shaping a world where responsible choices lead to superior products. Explore the full potential by clicking to unveil how NVTPE is revolutionizing the eco-conscious materials landscape.

Discover the heart of NVTPE's commitment at our Raw Materials Hub. From end-of-life tires to recycled Polypropylene (PP) and High-density Polyethylene (HDPE), we're redefining materials for a cleaner, greener future.

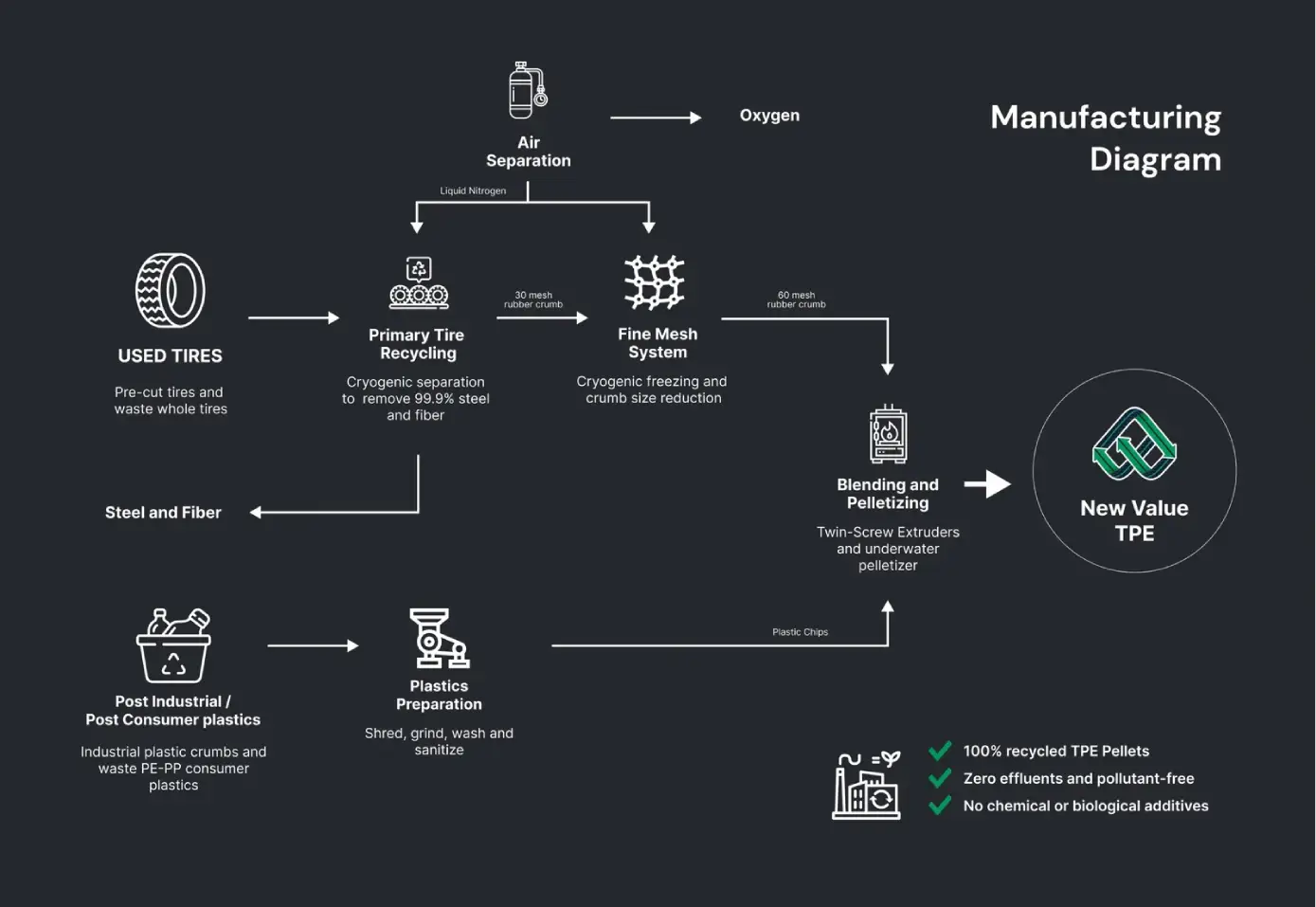

While pursuing sustainable manufacturing practices, NVTPE emerges as a leader with its highly revolutionary 100% recycled TPE sphere. These guns mean more than just the product; They share a strong commitment to environmental responsibility and cutting-edge technology. Carefully produced from end-of-life tires and post-industrial plastic waste (PP and HDPE), NVTPE pellets reflect a blend of sustainable sourcing, advanced cryogenic technology and consumer products in a variety of ways, making it a force in business at the forefront.

Learn More

In sustainable manufacturing, the process of manufacturing thermoplastic elastomers (TPE) stands as a testament to innovation, recycling and environmentally responsible TPE, a versatile material with a stable resource that can be carefully designed recycling life tire is repurposed helps to

The journey begins with an ending stack of tires, which goes through a winding road separation. This state-of-the-art technology provides efficient and uniform wear of tire parts, allowing for recycling. The most important step in bead making follows, focusing on the removal of the inner rim, known as the bead, which is attached to the rim. This careful process ensures that subsequent steps focus on increasing the rubber content of the tire, which is a key element in the production of high quality TPE

Crafting the essence of sustainable TPE Then debeading is the grinding process of shredded tire parts, making the material into a finer, uniform rubber powder This lays the foundation for the mixing and blending phase, where rubber is ground with recycled polypropylene (PP), high density polyethylene (HDPE), among others Combining materials or these fine mixtures produces a balanced mixture, enhancing the quality of TPE. The mixture is then extruded, a revolutionary process in which it is heated and forced through a die to form its continuous shape or form, allowing many desired products to be produced for a variety of materials

At NVTPE, we extend an invitation to visionary investors and industry leaders to collaborate in forging a sustainable future. Joining hands with NVTPE means becoming a catalyst for positive environmental impact and reshaping industries. As we navigate the transformative landscape of recycled TPE pellets, we recognize the power of collective efforts. By aligning with NVTPE, you enter a network dedicated to propelling a cleaner, greener tomorrow. Explore boundless partnership opportunities by clicking here, and let's embark on a journey where innovation and sustainability converge for lasting change. Your investment isn't just financial; it's a commitment to a future where environmental responsibility meets unparalleled industry transformation.

Meet the minds driving NVTPE's commitment to innovation and sustainability. Our diverse team brings expertise and passion to tire recycling. Join us in building a future where environmental responsibility meets cutting-edge technology.

Eberhard Lucke

CEO

Stan Spears

Director of Business Development

Guita Madhi

Principal Process Consultant

Indira Hemawatee Ramroop

COO

Claudette Charpenter

CHIEF FINANCE OFFICER

Dive into NVTPE's world through insightful blogs. Stay updated on industry trends, sustainable practices, and the latest in tire recycling technology. Join our community shaping the narrative of a more eco-conscious future.

In 2019, LCTS embarked on a visionary quest in collaboration with RTI Cryogenics Inc. The goal was to explore the...

mc bumagat

In the pursuit of a sustainable future, innovative solutions that address environmental challenges are more crucial than ever.

mc bumagat

We want to hear from you

163 Ryder Lane,

Callaway, Florida, USA

+1(281) 636-1306

info@nvtpe.com